We give you back your most beautiful smile

Z-SYSTEMS ceramic implants are the best option for replacing missing teeth. With them, you can confidently and joyfully show off your smile.

What is a dental implant?

A dental implant is an artificial tooth root that is inserted into the jawbone to replace a missing tooth. It serves as a stable base for a dental prosthesis such as a crown, bridge or denture. The implant feels like a natural tooth and helps to restore a beautiful smile and normal dental functions. Ceramic dental implants are a modern and effective solution to improve the appearance and functionality of your teeth.

Z-SYSTEMS implants are high quality ceramic implants, 100% Swiss Made, with over 20 years of worldwide experience.

Your advantages with our ceramic implants

More natural.

Since our metal-free implants are all made of biocompatible zirconium oxide (= ceramic), tissue compatibility is very good - bone and gums attach better than with metal-containing implants.

Healthier.

Z-SYSTEMS implants are metal-free, biocompatible, do not conduct heat or electrical energy and do not irritate the immune system. They are less sensitive if you eat something very cold or hot.

More sustainable.

Our ceramic implants accumulate less plaque than metal implants, which reduces the risk of gingivitis, cardiovascular diseases and strokes.

Harder.

Our ceramic implants are harder than metal and do not bend.

More aesthetic.

Unlike metal implants, the white ceramic material means that no gray shade is visible even with thin or receding gums.

More visible.

Our ceramic implants are radiopaque and easier to recognize in critical situations.

"Z-SYSTEMS is my first choice in Aesthetic dentistry. For patients who think holistically and care about a harmonious interaction with their bodIES, these ceramic implants are simply second to none. Metals tend to trigger reactions in the body, but with the exceptional biocompatibility of Z-SYSTEMS ceramics, you can be sure that your dentures will be optimally tolerated.

With Z-SYSTEMS, you not only get aesthetically pleasing results, but also the peace of mind that your health is the main focus."

Kian Dilmaghani

Implantologist, Basel

O-Ton mit Video von Dilmaghani

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

How implant treatment works

Implant treatment involves several steps. First, the ceramic implant is firmly inserted into the jawbone, where it acts like an artificial tooth root. After a healing phase, during which the implant grows into the bone, the visible part of the dental prosthesis is attached to the implant like a crown or bridge. The result is a fixed and natural replacement for your missing tooth that restores your smile and normal tooth function and is a permanent solution for a beautiful and healthy set of teeth.

-

1st Step

Consultation and preliminary examination

Before inserting your dental implant, you will have a thorough consultation during which your dentist will evaluate your individual situation and discuss important health aspects with you. The dentist will inform you about regular check-ups and aftercare, as well as the importance of conscientious care and good oral hygiene.

-

2nd Step

Clinical examination

Your dentist will carefully examine your mouth and check your teeth, gums and bone structure. X-rays are taken to determine the condition of the jawbone. With these findings, your dentist will create a customized treatment plan for you.

-

3rd Step

Tooth extraction

Tooth extraction is a painless procedure in which a damaged tooth is removed to make room for the implant. First, the tooth is anesthetized so that you do not feel any pain. The tooth is then carefully removed. After the extraction, the Z-SYSTEMS ceramic implant can be inserted into the vacated area and replace your missing tooth. Your dentist will ensure that you are well cared for during the entire procedure.

-

4th Step

Implant surgery

A Z-SYSTEMS implant is inserted into your jawbone to replace the missing tooth. The procedure is performed under local anesthesia so that you do not feel any pain. Your dentist makes a small incision in the gum, inserts the implant and sutures the site. After a healing phase, the ceramic implant grows firmly into the bone. Your dentist will look after you throughout the entire process.

-

5th Step

Postoperative follow-up examination

and suture removalYour dentist will carry out a follow-up examination to ensure that your ceramic implant is healing well. They will check that everything is going as planned and that you have no complications. Another important phase is the suture removal, where the sutures are removed as soon as the wound has healed sufficiently. This step is usually painless.

And you will soon be smiling your brightest smile again!

A pioneer in ceramic dental implants since 2004

Place your trust in the global market leader for ceramic implants. All our products are developed and manufactured in Switzerland.

With around 100,000 implants placed and more than 20 years of experience, our ceramic dental implants are currently the best in the world. With the most stable implant connection and the highest fracture resistance, we offer you maximum safety.

The world's only Swiss-made 100% ceramic implant

Z-SYSTEMS Swiss-made 100% ceramic dental implants are superior implants because of the superior Swiss manufacturing process. Our implants offer you a long-lasting and aesthetically pleasing solution for a healthy and beautiful smile that lasts a lifetime.

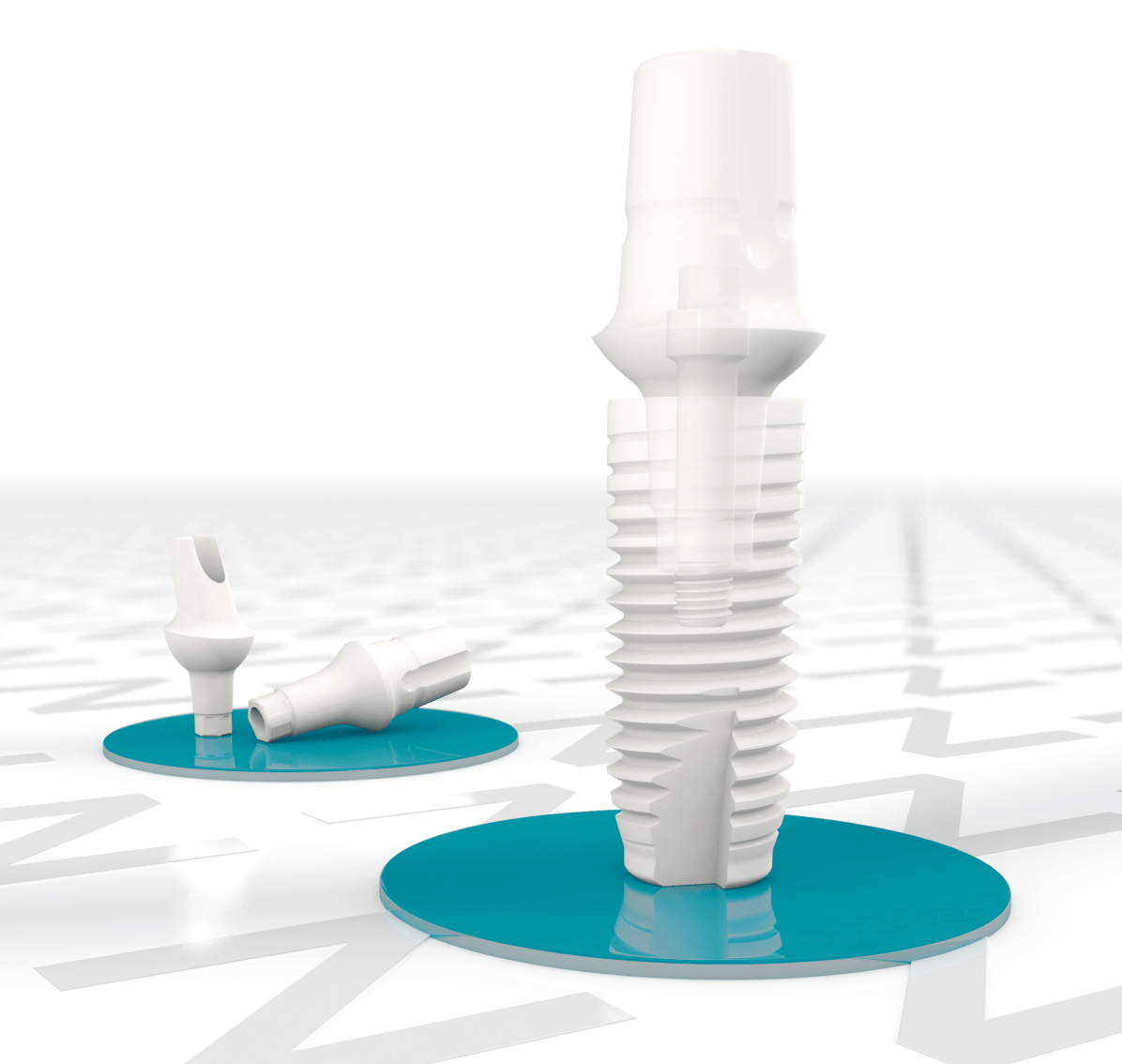

The world's only 2-piece 100% ceramic implant

Our high-quality, two-piece ceramic dental implants provide natural aesthetics and are extremely stable. The excellent material compatibility offers you a safe and long-term solution. The high biocompatibility promotes tissue regeneration and a comfortable wearing experience. Your health is our top priority.

Over 100,000 Z-SYSTEMS implants placed worldwide

We have been offering innovative and high-quality ceramic implants as tooth replacements for over two decades. With over 100,000 implants placed, you can rely on our advanced technologies and treatments. Put your trust in the world's best solution since 2004.

FAQ

Are ceramic implants suitable for everyone?

Are ceramic implants covered by health insurance?

Is zirconium oxide really metal-free?

How do I find a dentist who inserts Z-SYSTEMS implants?

If you contact us (by e-mail or telephone), we will be happy to tell you who places our proven ceramic implants in your area.

I suffer from allergies. What do you recommend?

We not only offer implants made of 100% ceramic, but also the dental instruments and screws made of ceramic to ensure a completely metal-free full restoration. This is the best alternative for allergy patients.

What questions should I ask the dentist before treatment?

1. am I a suitable candidate for a dental implant?

2. what type of implant is recommended and why?

3. what is the implant treatment procedure?

4. what are the risks and complications associated with implant treatment?

5. how long does the healing time and recovery take after the operation?

6 What kind of care and aftercare do I need?

7. what costs are associated with implant treatment and which of these are covered by health insurance?

What is the advantage of Zirkolith®?

Zirkolith® shows an extremely low build-up of bacterial plaque, the main cause of gum disease such as periodontitis. Untreated periodontitis can increase the risk of a variety of organic diseases such as diabetes, pregnancy risks, osteoporosis and cardiovascular diseases.

What are the disadvantages of titanium implants compared to ceramic implants?

Metal implants can lead to allergic reactions or titanium intolerance.

It can cause discomfort since metal conducts electrical energy.

With receding gums or thin bone, the dark grey color of titanium can shine through and be unsightly.

Why should I choose a ceramic implant from Z-SYSTEMS?

Our ceramic implant is 100% metal-free and has excellent tissue compatibility.

White ceramic is very esthetic for a radiant smile.

Our ceramic is biocompatible with excellent tolerance for the body and very good regeneration of the gums.

We have over 20 years of worldwide research experience and are considered very safe.

What should I do if I lose an implant?

Is zirconium oxide immunologically safe?

No intolerance reaction to zirconium oxide particles has been detected in blood laboratory tests to date. The all-ceramic zirconium oxide implants are therefore considered immunologically safe.

Dentist and implantologist recommendations for you

Are you looking for a qualified dentist in your area?

We are happy to recommend the best.

Z-Systems Online Magazin

"L'implant en zircone: une alternative au titane"

Wie Keramikimplantate die Knochenregeneration fördern: Erkenntnisse und Vorteile

Setzt Ihr Zahnarzt Keramikimplantate?

Titan-Unverträglichkeit ist keine Allergie

Webinar: Optimizing Ceramic Dental Implant Osseointegration with Dr. Sebastijan Perko

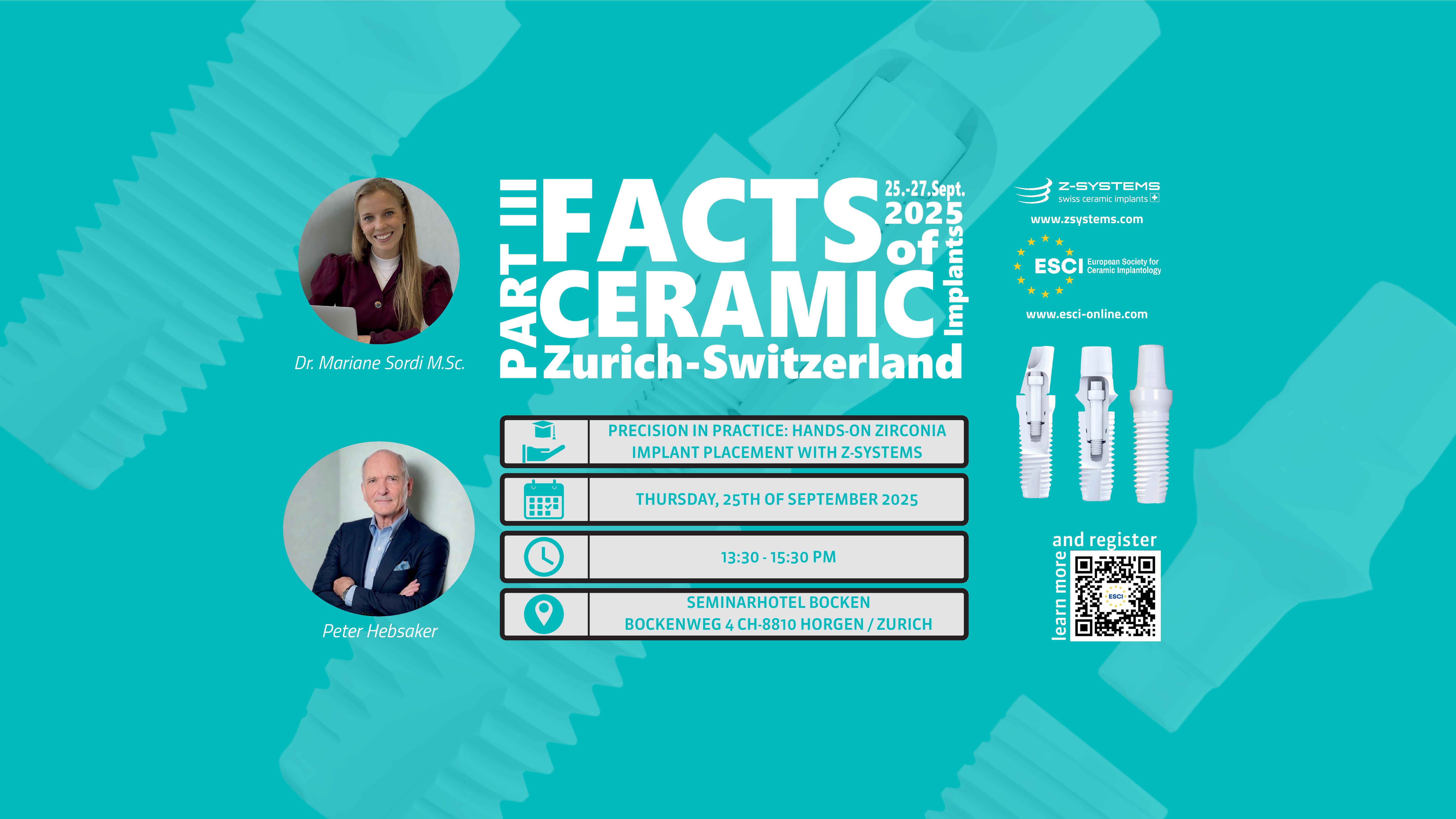

ESCI 2025 in Zürich: Innovationen für die Zukunft der Zahnmedizin

Webinar: Zirkoniumdioxid-Implantate – Einblicke von Dr. Norbert Cionca

SwissPerio IQ 2025: Ein Muss für Fachleute der Implantologie

Webinar: am Mittwoch, 19. März 2025 mit Prof. Dr. Dr. h.c, Mutlu Özcan